In the world of heavy machinery maintenance, certain specialized processes ensure longevity and optimal performance. Among these, line boring, on-site machining, bore repair, and bore welding stand out as indispensable techniques.

Line Boring: Precision Redefined

One essential maintenance service is line boring. This process involves the precise enlargement of an existing hole to achieve a perfect cylindrical shape. Often, machines experience wear and tear, causing misalignments. Line boring rectifies these issues, restoring the machinery to its original specifications.

On-Site Machining: Convenience Meets Expertise

On-site machining takes the capabilities of a machining workshop directly to the worksite, minimizing downtime and transportation costs. This service includes tasks such as slew milling and xy milling, ensuring precision without the need to disassemble large equipment.

Bore Repair: Extending Equipment Lifespan

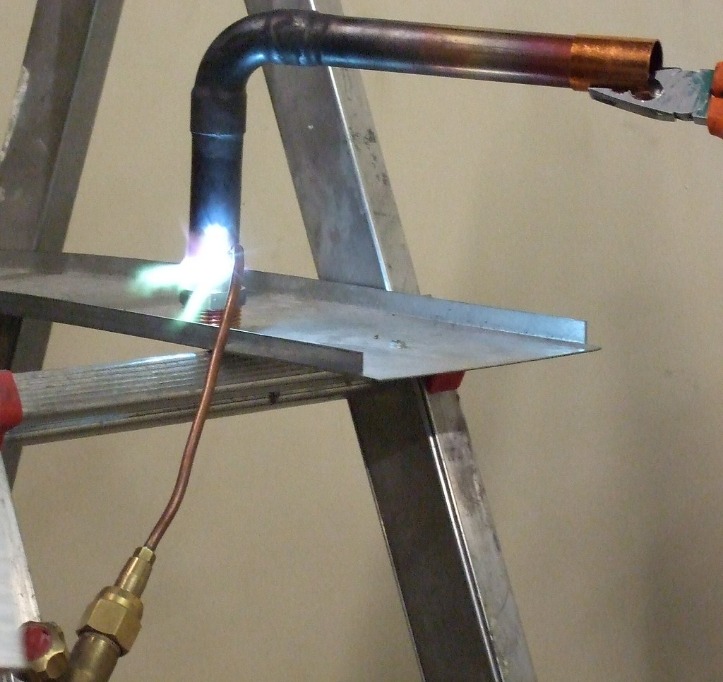

Regular usage of machinery can lead to wear in the bores, impacting the overall functionality. Bore repair techniques, including methods like bore welding and face welding, are employed to mend these worn-out areas. This process restores the bore’s original dimensions, effectively prolonging the machinery’s life.

Read more about xy milling here.

Bore Welding: Rebuilding from Within

Bore welding involves adding material to the worn areas of a bore. This added material is then machined to the correct size, ensuring a precise and durable repair. Similarly, face welding addresses wear on flat surfaces, enhancing the equipment’s reliability.

Bush Install: Securing Component Longevity

For added durability and reduced wear, bush install services are often necessary. This involves placing a metal sleeve inside the bore, which protects the inner surface from direct contact with other moving parts, reducing friction and wear.

Slew Milling and XY Milling: Versatile Machining Solutions

Slew milling and xy milling are advanced machining processes used to maintain and repair various large-scale industrial equipment. Slew milling is particularly useful for milling rotary components, while xy milling offers precision in both horizontal and vertical planes.

Conclusion

The integration of line boring, on-site machining, bore repair, bore welding, slew milling, xy milling, bush install, and face welding demonstrates a comprehensive approach to industrial machinery maintenance. These techniques not only repair but also reinforce and extend the life of critical equipment, ensuring uninterrupted performance and operational efficiency.