In the world of heavy machinery and industrial maintenance, the demand for precision, efficiency, and minimal downtime is paramount. This is where services like Line Boring, on-site machining, bore repair, and related techniques such as bore welding, slew milling, and xy milling come into play. These methods are critical in ensuring that industrial machinery operates flawlessly, thereby reducing costly interruptions.

The Importance of Line Boring

Line Boring is a specialized service that ensures the consistency and precision of bore alignments in heavy machinery. Common applications include:

-

Read more about on-site machining here.

- Restoring worn bores to their original specifications

- Preparing bores for new bearings or bushings

- Ensuring alignment for mechanical efficiency

Advances in On-Site Machining

Traditionally, heavy machinery adjustments required extensive disassembly and transportation to specialized workshops. With on-site machining, these challenges are addressed directly at the location of the machinery. This process significantly reduces both costs and downtime. Key on-site techniques include:

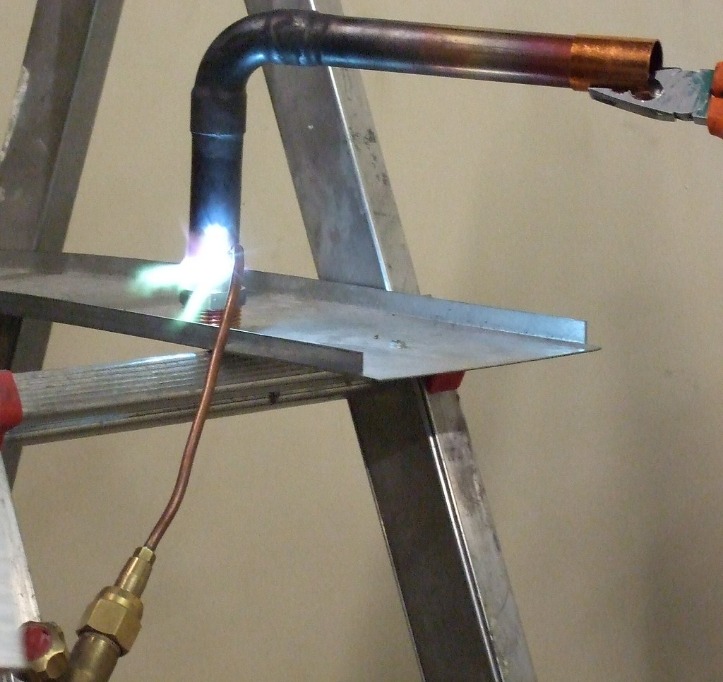

Bore Repair and Welding

This essential maintenance involves the restoration of damaged or worn-out bores. Bore repair typically employs bore welding to build up and restore worn areas, followed by precision machining.

Slew Milling and XY Milling

Slew milling and xy milling are versatile procedures used in the re-machining of critical parts. These methods allow for precise material removal and surface preparation, maintaining the machinery’s integrity and extending its operational life.

Additional Essential Services

Complementing the aforementioned techniques, other pivotal services include:

Bush Install

After bore repair and welding, the installation of new bushings restores the motion components and ensures a snug fit. This process is critical for maintaining the equipment’s efficiency and operational lifespan.

Face Welding

Face welding is often used to refurbish surfaces that interact with other components. This method enhances wear resistance and preserves the efficiency of mechanical interfaces.

FAQs: Enhancing Understanding of Key Services

- What is Line Boring?

- An advanced machining process used to correct and restore the alignment of bores in heavy machinery.

- Why choose on-site machining?

- It minimizes downtime and transportation costs by allowing repairs and adjustments to be made directly at the machinery’s location.

- What is bore welding?

- A technique used to repair worn bores by adding material through welding and then machining it to the correct dimensions.

- How does slew milling differ from other milling techniques?

- Slew milling involves a rotating head that can move in multiple directions, allowing for more complex and precise cuts.

- What is xy milling?

- A type of milling where the cutting tool moves in XY (horizontal) directions, ideal for flat surfaces and precise machining.

- Why is face welding important?

- It refurbishes surfaces that make contact with other parts, enhancing their wear resistance and prolonging the component’s lifespan.

Industries relying on heavy machinery can’t afford prolonged downtimes or inefficient equipment. Employing techniques like Line Boring, on-site machining, bore repair, bore welding, slew milling, xy milling, bush install, and face welding ensures the longevity and precision of vital machinery components. These services not only enhance operational efficiency but also deliver substantial cost savings over time.